– Showcasing Cutting-Edge PVD Technology for Architectural Stainless Steel Applications

Double Stone Steel, a leading innovator in stainless steel surface treatment solutions, has been officially invited to participate in the Jangho Curtain Wall Global Supplier Summit 2024. The event will be held in Guangzhou in November 2024, where Double Stone Steel will present its advanced PVD coating technologies and customized surface finishing solutions for high-end architectural applications.

Revolutionary PVD Technology Advantages

With 30 years of expertise in stainless steel surface engineering, Double Stone Steel's PVD (Physical Vapor Deposition) coating delivers unmatched performance:

Superior Durability – Passes 3,000-hour salt spray tests, ideal for coastal and high-pollution environments

High adhesion and durability: During PVD coating, ions bombard the surface of the workpiece at high speed, which can penetrate the surface of the workpiece and form a diffusion layer that is deeply injected into the substrate, so that the film layer and the substrate form a good bond and adhere firmly. The coating can plastically extend with the base metal without peeling or flaking, and can be bent more than 90 degrees without cracking or flaking.Dense and uniform structure: The PVD coating film is uniform and dense, without pinholes, bubbles, and uniform thickness. The edges and grooves can be evenly plated without forming metal nodules.

Vibrant Color Options – Over 100 premium finishes including Rose Gold, Champagne Gold, Almond Gold, Titanium Black, etc.

Diverse color selection: PVD vacuum coating can be plated with a variety of colors, such as IPG light gold, IP gold, IP furnace rose gold, IP coffee color, IP chrome, IP gray, brown, IP black, gun color, etc., which makes the product appearance more colorful and meets different aesthetic needs.Improve the decorative performance of the appearance of the workpiece: The uniform and dense film layer can greatly improve the decorative performance of the appearance of the workpiece.

Eco-Friendly Process – Compliant with EU REACH standards, free from heavy metals and harmful chemicals

Pollution-free: Compared with the traditional electroplating process, PVD coating technology does not produce toxic wastewater and exhaust gas, and is a pollution-free and environmentally friendly surface treatment method.Energy saving: During the coating process, the PVD coating process can make full use of evaporating substances, reduce energy waste, and achieve energy saving effects.

Long-Lasting Beauty – Nano-layer coating ensures color retention for 15+ years

High hardness and high wear resistance: PVD coating has extremely high hardness and wear resistance, and its low friction coefficient enables the coating to maintain excellent wear resistance in various environments.Good corrosion resistance and chemical stability: PVD coating can maintain the performance of anti-oxidation, non-fading, non-loss of gloss and non-marking under normal environment, including indoors and outdoors.

Easy Maintenance – Proprietary anti-fingerprint technology (110° contact angle) reduces cleaning costs by 40%

Why Choose Double Stone Steel?

Relentless Innovation – 8% annual R&D investment, holding 13 invention patents

Mass Production Capacity – 50,000㎡ annual output from 20,000㎡ smart factor

Total Customization – One-stop solutions from design to installation

Global After-Sales – 24/7 technical support with 15-20 years quality guarantee

PVD vacuum coating technology is widely used in automobiles, aerospace, electronics, optics, medical equipment, jewelry, watches, home decorations and other fields. In the automotive field, PVD coating can improve the hardness, corrosion resistance, wear resistance and scratch resistance of the body surface, and can also increase the gloss and aesthetics of the body. In the aerospace field, PVD coating is used for the protective film layer of the shell to resist extreme space environments such as solar radiation and micrometeoroid impact. In the electronics field, PVD coating is used to form conductive paths and insulating layers on circuit boards.

"Our new ShieldPro™ series combines PVD coating with nano-ceramic layers. It provides exceptional scratch resistance and UV protection – perfect for super-tall curtain walls."

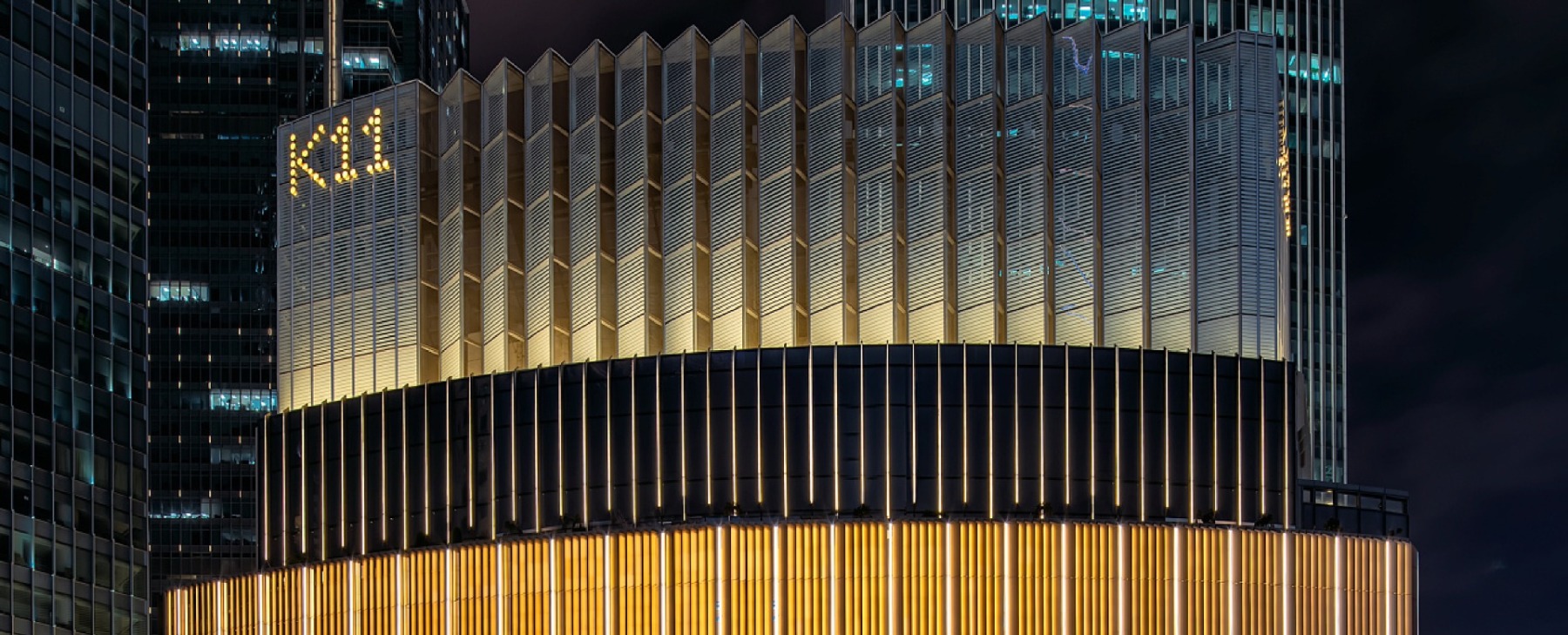

Double Stone Steel’s technologies have been applied in landmark projects. We are looking forward to cooperating with you.