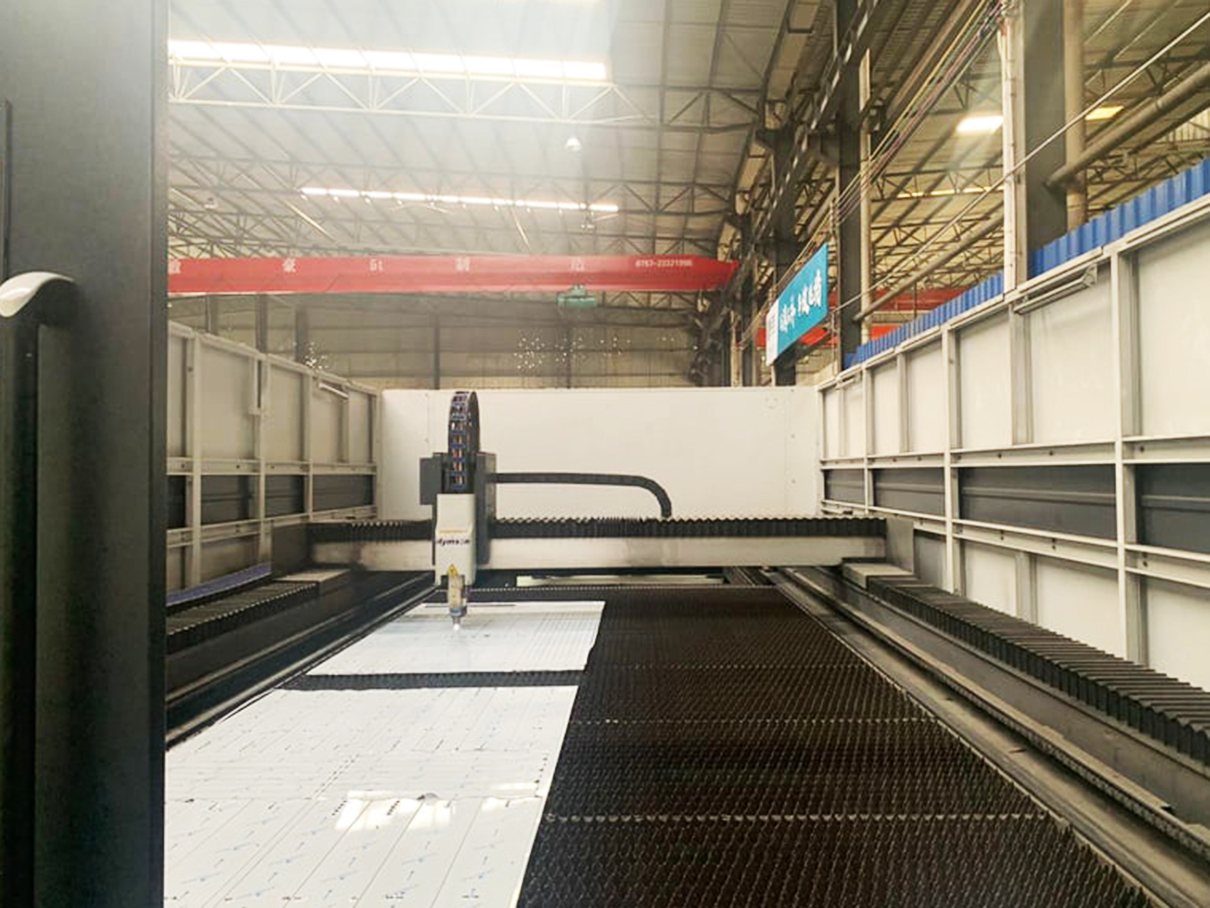

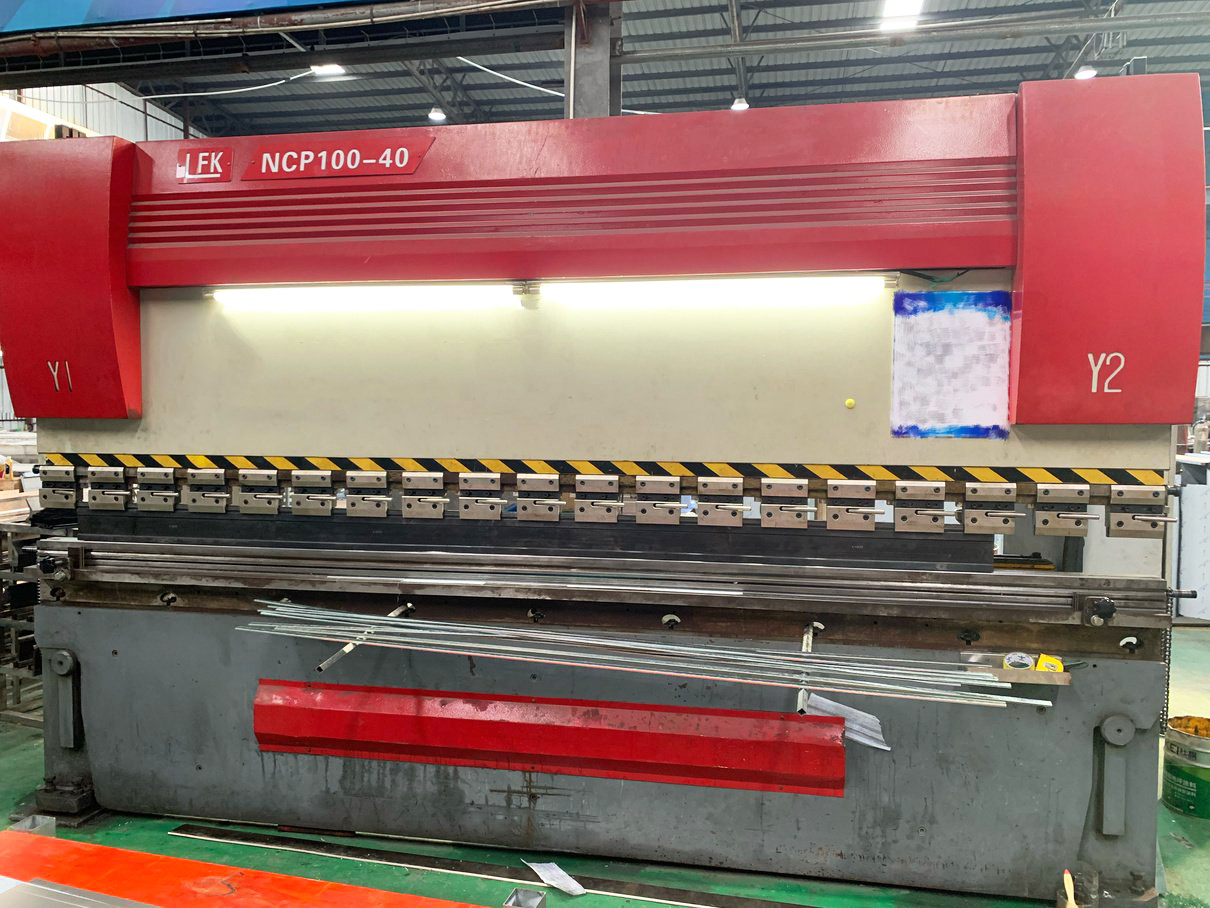

Double Stone has over 60 PVD machines of various capacities and this makes us very flexible. We can deal with a maximum profile size of 1800mm diameter and 5000mm length, Our maximum sheet size is 3*1500*6000mm. Double Stone's PVD products are widely applied in both Interior and exterior projects, windows and doors, hotel furniture, point-of-sale displays, electrical Appliances, sanitary ware, light fixtures, door hardware, auto parts, and kitchenwares, really the list is endless.

DoubleStone has a strong technical force and an experienced team. Until now it has developed over 100 PVD colors. The main colors include GoldSeries, RoseGold Series, BlackSeries, Red Rose Series, Rainbow Series, Antique Series, Dark Gold Series, and Transparent Series.

DoubleStone always makes qualified products. We are looking forward to your cooperation.

The titanium nitride film prepared by vacuum ion plating has a dense microstructure. The salt spray resistance and wear resistance of the product are better than those of the film prepared by electrochemical coloring.

According to the experimental results, the colored decorative coating prepared by ion plating has a stronger bonding force between the film and the surface of the workpiece, and the performance is more stable; the film has a higher hardness, better wear resistance and corrosion resistance, a wider range of film types, and more and more beautiful colors of various film layers that can be plated; at the same time, PVD coating does not produce toxic or polluting substances; its service life can reach 25 years.

★Wide range of deposition materials: low-potential metals such as aluminum, titanium, and zirconium that cannot be deposited by wet electroplating can be deposited.

★Through the reaction gas and alloy target, coatings from alloys to ceramics and even diamonds can be deposited.

★The coating system can be designed according to needs.

★The adhesion, density, hardness, and corrosion resistance of the vacuum coating are quite excellent.

★The deposited coating can be much smaller than the conventional wet electroplating coating, achieving the purpose of saving.

★Plasma is deposited on the surface of the workpiece in a vacuum environment, and there is no solution pollution, so the harm to the environment is quite small