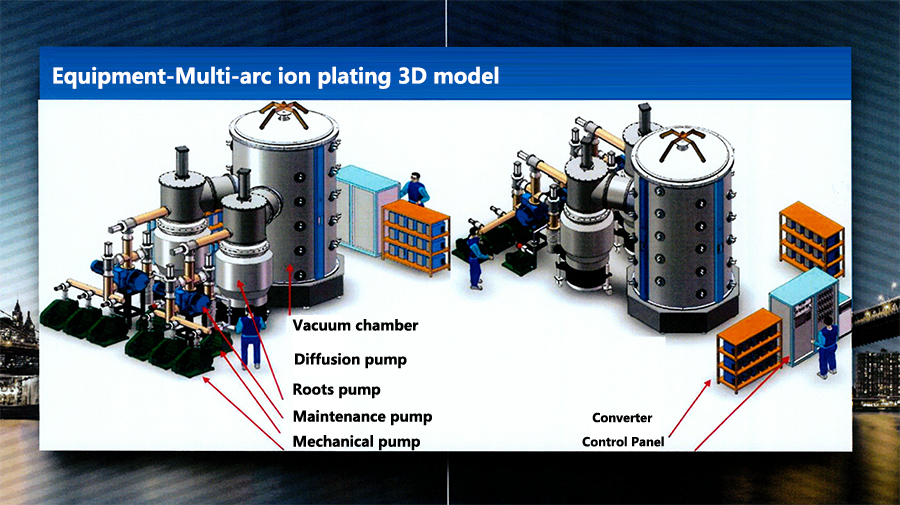

Equipment-Multi-arc ion plating 3D model

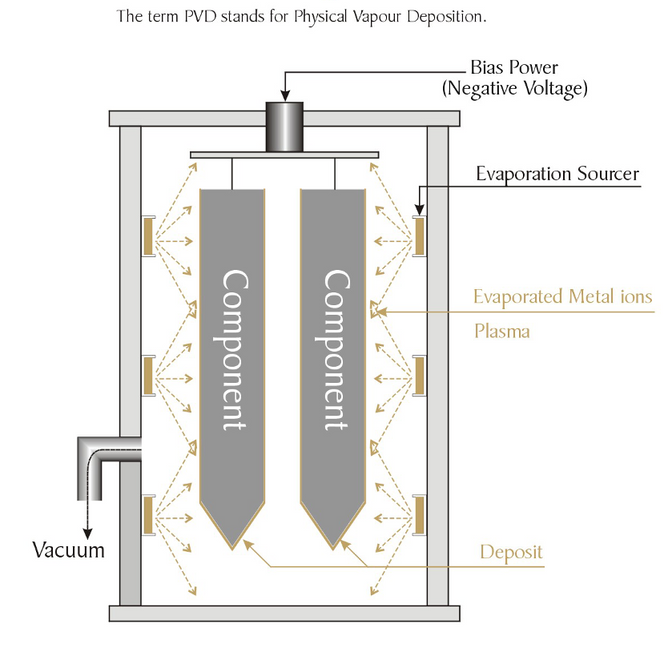

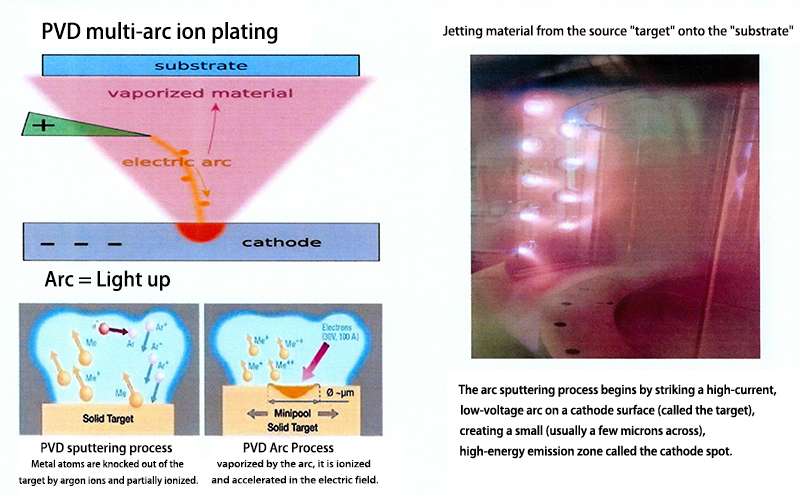

Ion plating technology was first proposed by D.M.Mattox of Sandia Corporation in the United States in 1963. It is a new coating technology developed on the basis of vacuum evaporation and vacuum sputtering. The full name of ion plating in English is lonPlating, referred to as IP. It is a process of coating by applying gas discharge under vacuum conditions, that is, ionizing the gas or evaporated material in the vacuum chamber, and under the bombardment of gas ions or evaporated material ions, the evaporated material or its reaction products are simultaneously evaporated on the substrate.

Advantages of PVD multi-arc ion plating:

1. The film layer has beautiful and colorful colors, rich varieties, delicate and smooth, good metal texture and gloss. PVD technology has strong vitality. Through continuous process research and development, there are nearly 100 colors such as gold, black, copper, blue, green, etc. to choose from.

2. The film layer has high density, high hardness, wear resistance, corrosion resistance, low friction coefficient and other excellent properties. Scratch-resistant, not easy to scratch, not easy to fall off and crack, and stable chemical properties-corrosion resistance, acid resistance, oxidation resistance; not easy to discolor, fall off, damage, etc.; stable performance in harsh environments such as hot sun and humidity.

3. The film layer has strong adhesion and can be bent more than 90 degrees without cracking or peeling (PVD coating has high adhesion and durability), which other technologies, including electroplating and spraying, cannot match.

4. PVD technology is environmentally friendly and economical, and does not produce waste gas, wastewater, and other solid pollutants: it is a green high-tech industry encouraged and developed by the country; the film thickness is ultra-thin, and the nano-level structure can save a lot of precious metals.

5. Multi-arc ion plating technology is highly practical, has high production efficiency, and has uniform and stable color. At this stage, the equipment can plate large stainless steel plates and special-shaped parts, with a maximum diameter of 2 meters, a maximum length of 5 meters, and a maximum weight of 150 kilograms.